Covid-19 coronavirus is bound to have significant impact on global supply chains as it impacts all sectors of the economy. See graphs from the Spectator for illustration. It is also somewhat unprecedented as it in many area both supply and demand are impacted. Both our ability to consume and produce has in many areas been significantly impacted by many countries adopting long periods of lock-down. Covid-19 is therefore a systemic shock to the economy, and a systemic shock to supply chains.

Systemic Impact on Supply Chains

The danger with supply chains is that Covid-19 significantly disrupts what are now frequently called supply chain networks. Where the term network recognises the complex inbound and outbound interdependencies between organisations. Supply chain networks are difficult to fully map and understand. Couple to this a move in the economy post WWII towards lean supply chains. Where there are low levels of redundancy in the supply chain, and resources (in all senses of the word) are delivered just in time. Disruption in one part of the network can quickly spread (cascade) to other areas. This could cause the network to fail in unpredictable ways. Where the ability of an organisation to produce something being halted by it being unable to acquire an essential input. Materials, parts, service, resources in general.

Supply Chain Deadlock

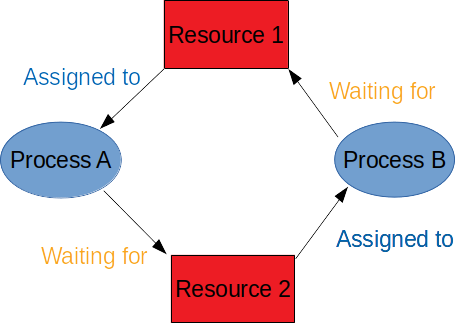

The danger with a large scale systemic shocks is that they sufficiently disrupt something like a supply chains to the point where it can no longer function. In the case of supply chains and Covid-19, one possibility is that they become deadlocked. The term deadlock is perhaps most frequently used to describe a situation where a series of interdependent processes all stop because they are all waiting for each other to do something. Process A is waiting for process B, B is waiting for process C, and C is waiting for process A. A situation that computer programmers have long had to deal with an mitigate.

This situation of deadlock could arise in lean supply chains. The operations of one organisation may be halted due to it being unable to acquire some essential resource for its operations. The halting of this organisation’s operations could have effects elsewhere in the supply chain. The difficulty is that this might not be a simple, easily mapped, supply chain. Similar to that shown above. Instead it might be a complex network of interdependent relationships, and therefore understanding how to release the deadlock might be extremely difficult.

International Coordination

If Covid-19 causes deadlock, releasing this deadlock in global supply chains will require international coordination. For example, it might require organisations to temporarily produce resources that they normally wouldn’t. Or resources might have to be moved between organisations. Both to allow processes in other organisations to get underway. There will need to be some way to both map resource requirements, and move them. This will need to be done internationally. Perhaps through the production of an international register of needs are resources.